Products

Here you’ll find more information about our cutting tools, available in various materials.

Application

Our application engenieers support you on the machines using our tools made of PCD, CVD, CBN or UltraDiamond.

Cutting materials

Find out more about our ultra-hard diamond cutting materials such as CVD-D, PCD and CBN.

Company

Read more about DTS and our lasertechnology to process diamond tools.

Webshop

Take a look at our webshop under shop.diamond-toolingsystems.com. Here you can shop diamond tools 24h a day.

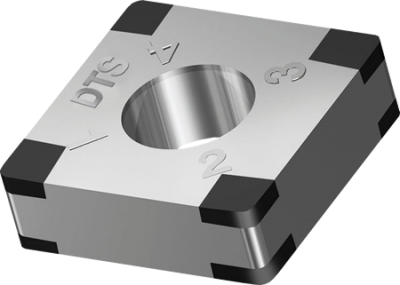

Turning

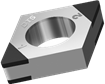

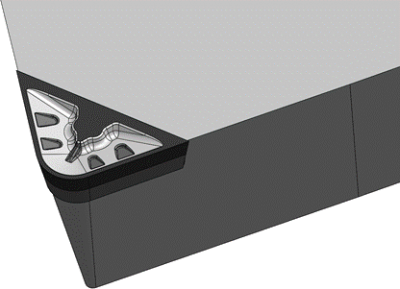

PCD and CVD-D Turning inserts

Take advantage of our selection of diamond inserts

CBN Turning inserts

Inserts tipped with 12 different grades for 5 different material groups

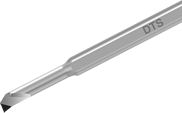

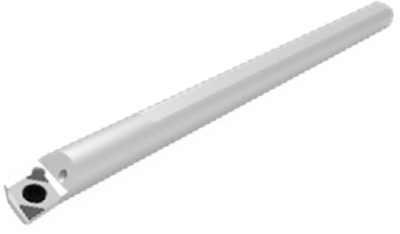

Boring tools starting form Dmin ∅0,80mm

Brazed diamond and CBN boring bars

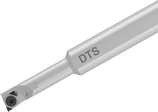

Boring bars with mini-inserts from ∅ 3,50mm

MiniTools with multi-edge-tipped inserts with Diamond and CBN

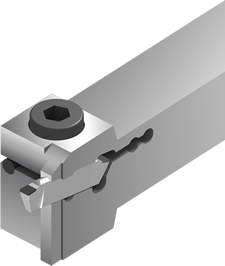

Grooving tools starting from W1,00 – 6mm

Grooving with diamond and CBN grooving systems

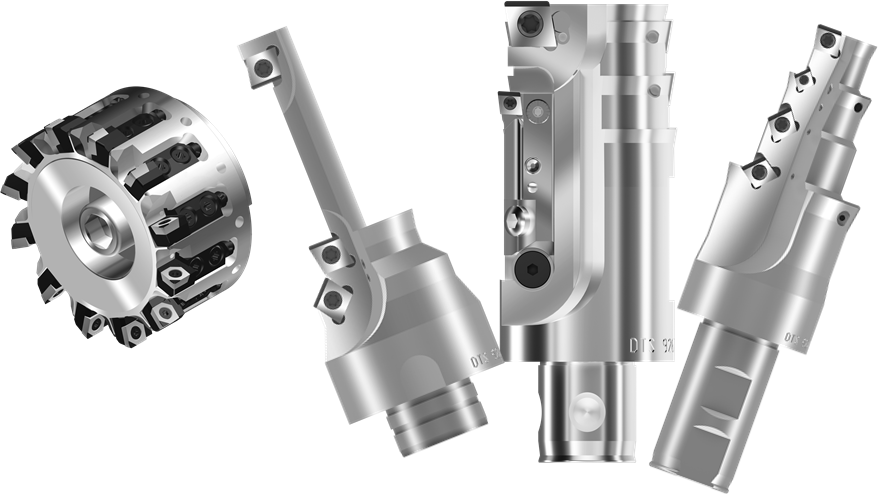

Milling

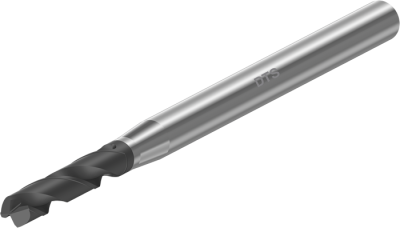

Diamond or CBN end mills ∅ 0,20-20mm

Milling tools made from CBN and diamond

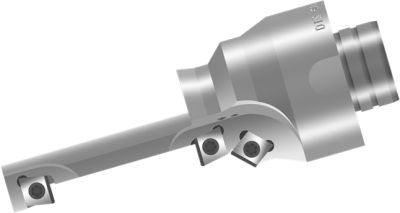

End mill with indexable inserts tipped with diamond or CBN ∅ 10 – 25mm

End mill for multiple egde tipped inserts.

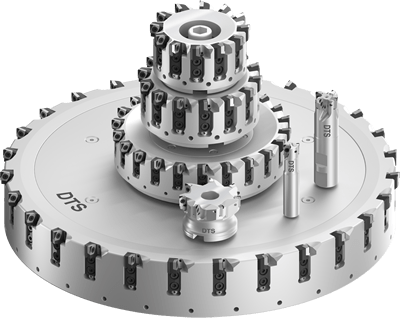

Milling cutter systems ∅ 32 – 400mm

Milling systems for multiple edge tipped diamond and CBN inserts

Drills / Reamers

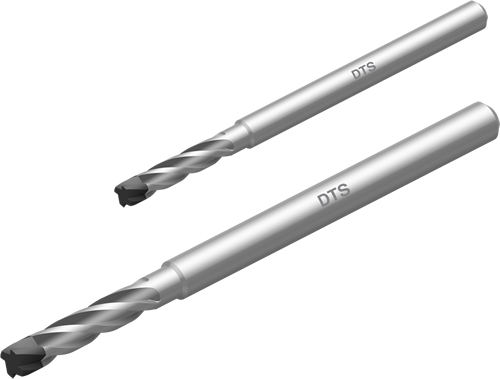

CBNCoat Drill starting from ∅ 2 – 12mm

These drills are developed for drilling in hard to machine- or hardeneed materials.

CBN reamers from ∅ 1.50 - 6mm

CBN reamers for reaming hardened materials

Chip breaker, Special tools , Adapters and Resharpening

Standard and special chip breaker

If you have problems with the chip control you can use our chip breakers

Special tools on request

We are prducing every kind of standing or roatating tools for you. Adjusted on the needings of your process and material

Tool holders

Stable holders for external machining, as well as low-vibration boring bars made of solid carbide and heavy metal

Resharpening of PCD, CVD-D and CBN

Regrinding service for PCD, CVD-D and CBN tools

Resharpening of standard and special tools

Cutting materials

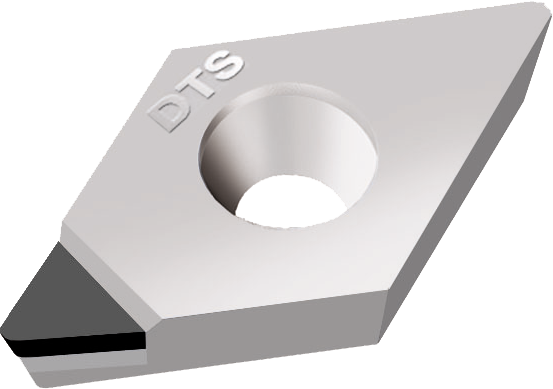

PCD

Polycrystalline Diamond (PCD), the well known Standard-Diamand

CVD-D

CVD-Thickfilm Diamond (CVD-D), the star among the diamond cutting materials

UltraDiamond

Binderless Diamand (UltraDiamond)

the hardest monocrystal

CBN

Cubic boron nitride (CBN), for machining hardened, carbon-containing materials, castings and special alloys

Application range for our ultra hard cutting materials

With our tools tipped with PCD, CVD-D, UltraDiamond or CBN you can machine these materials among others:

Hard-turning

Hard milling

Tool steel

Carbide

Ceramics

Quartz glass

Aluminum

Copper

Zinc

Cast iron

Inconel

Stelite

The full range of diamond tools

Years ago, we at DTS set ourselves the goal of being able to offer the widest possible range of diamond and CBN tools with laser-cut ultra-hard cutting materials of the highest quality. Since 2022, we have achieved it: we can now offer the right PCD, CVD-D, UltraDiamond or CBN tool from stock for many cutting applications.

The result is a total of 8 tool groups (diamond inserts, CBN inserts, boring tools / solid PCD and CBN MiniTools, end mills, milling head systems, grooving systems, drills & reamers, holders & boring bars), in each of which we have been able to incorporate our 25 years of experience as process optimizers to create a range that is unique in this breadth at the highest level of quality and at competitive prices.

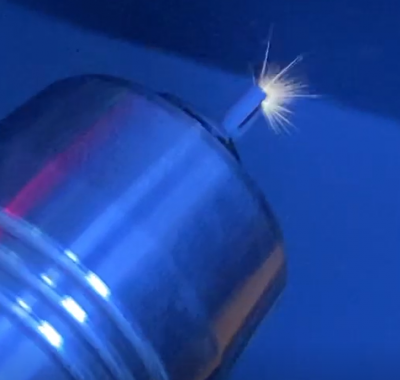

We have focused on laser cutting from the very beginning. Today, this long-standing expertise gives us a clear advantage in the market when manufacturing our high-tech tools.

24-hour access to laser-cut diamond and CBN tools

With the help of our web store, you have the opportunity to view our stock and your final prices 24/7. Intuitively and easily, you can quickly find the right PCD, CBN, UltraDiamond or CVD-D tool for you.

This web store for ultra-hard cutting materials offers you tools from the following product groups: Turning, Milling, Grooving, Drilling, Reaming, MiniTools, Holders and Boring bars.

What are diamond and CBN tools?

The shank or base body of our tools is usually made of carbide. Corresponding segment seats are attached to this base carrier, into which we braze the corresponding diamond or CBN using high-vacuum brazing technology. This process provides a secure interface under extreme machining conditions with high heat.

What diamond and CBN tools are available?

Diamond and CBN tools are available for all types of machining tasks such as turning, milling, drilling, reaming, grooving, threading and spindles. At DTS, we can also manufacture diamond and CBN tools for you as special tools, for example to carry out several machining steps at once. It is also possible to apply a complex contour to contour tools.

What are diamond and CBN tools made of?

A diamond or CBN tool consists of a base carrier/base body and the actual cutting material: the diamond or cubic boron nitride CBN. This diamond can be a PCD (polycrystalline diamond), CVD diamond (chemical vapor disposition of diamond), ultra-diamond (single crystal) or CBN (cubic boron nitride).

Where are diamond and CBN tools used?

There is a wide range of possible applications for laser-cut diamond and CBN tools.

For example: aluminum, brass, magnesium, graphite, copper, tungsten alloys, acrylic, composite materials (CFRP, GFRP), concrete, plastics, glass, ceramics, hard metal, gold, zirconium, platinum, wood, titanium, hardened steels, cast iron, nodular cast iron, sintered metal, alloy steels, Inconel, tool steel, Stellite, stainless steel and PM steels.

Lasered diamond and CBN tools are used in a wide range of industries. We mainly supply the following industries: Automotive, aerospace, medical technology, mechanical engineering, toolmaking, mold making, optical industry.

How are diamond and CBN tools manufactured?

Diamond and CBN tools of all types - for turning, milling, drilling, grooving, threading, spindling and scoring - consist of a base body. This is usually made of solid carbide. A segment seat is ground into this base body. A piece of the corresponding ultra-hard cutting material is produced to fit this segment seat. This so-called “blank” is then brazed into the segment seat of the base body using high-vacuum brazing technology and thus secured. This has the advantage of creating a good connection between the base body and the diamond insert at high temperatures.

Last but not least, one of the most important steps follows: cutting edge preparation. Here, the cutting edges are either ground or lasered. Lasering is increasingly gaining a leading role here, as the quality, accuracy and structure of the cutting edge is significantly better than after grinding. High sharpness, high diamond content on the cutting edge, high-precision chamfer and rounding qualities are just a few examples of the advantages.

Why DTS?

We listen to our customers and they confirm our leading position for laser-cut tools in Europe!

To suit your needs, we offer: top quality, good availability, fast quotation preparation, professional support, design of processes and special tools, personal support on your machine and over 25 years of experience with diamond and CBN tools. These are just some of the reasons why you should rely on our systems and technicians.

Quality is safety

All the tools we offer you are of the highest quality “Made in Germany”. This is why we attach great importance to state-of-the-art production and measuring systems - we leave nothing to chance and rely on established partners. Our laser-cut diamond blades made from PCD, CVD-D, UltraDiamond and CBN offer you reliability for your process. In addition to long tool life and good surfaces on the component, you can achieve even greater process reliability with our chip breakers thanks to controlled chip breaking.

Added value through resharpening service

At our production site in Idar-Oberstein, we focus on the reworking of tools. All PCD, CVD-D, UltraDiamond and CBN tools are reground or reglassed here. We can offer real added value for your tools with defined diamond cutting edges, as often only a very small percentage of the diamond is used and disposed of after use.

DTS gives you the opportunity to have your tools re-sharpened, ideally several times, at a reasonable price. We would like to point out that we can offer our own worldwide patented resharpening system, please contact our sales representatives so that they can explain our unique resharpening system to you on site. Please note that we resharpen all tools from DTS as well as from our competitors!

The NEW resharpening of CBN by DTS

Are you one of those who use CBN indexable inserts but dispose of them as carbide scrap at the end of their service life? At DTS, we have found a solution that allows you to use your CBN tools multiple times. You can even continue to use your existing holders. We provide you with the necessary material and technical support for a system that is already being used efficiently in many cases.

Sustainability, Made by DTS.

Contact us!

DTS GmbH

Hans-Geiger-Strasse 11a

D-67661 Kaiserslautern

Customer service

Mo. - Fr. 8:00 - 16.30 Uhr

Contact details

F: +49 (0) 6301 32011-90