PCD milling - Polycrystalline diamond (PCD) milling cutter

What is PCD milling?

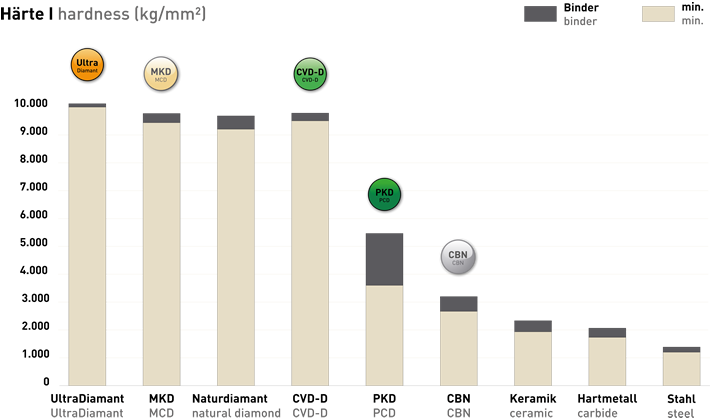

PCD milling describes the use of milling tools that are coated or manufactured with polycrystalline diamond (PCD). PCD is an extremely hard, synthetic material that is known for its high wear resistance and durability. PCD milling tools are particularly suitable for applications where abrasive or difficult-to-machine materials need to be milled precisely and efficiently.

What can be processed with it and what are the areas of application?

PCD milling cutters are ideal for machining materials that wear out quickly with conventional milling tools. Typical areas of application are:

- Aluminum with less than 10% silicon content: PCD milling cutters offer excellent tool life and surface quality when machining aluminum alloys with a low silicon content, which is particularly relevant in the automotive and mechanical engineering industries.

- Brass: PCD milling cutters are particularly suitable for the precise machining of brass, which is often used in electronics and sanitary applications. They enable smooth surfaces and reduce tool wear.

- Zinc: Zinc and zinc alloys, which are frequently used in the automotive and construction industries, can be machined efficiently and precisely with PCD milling cutters without causing excessive wear.

- Plastic: When machining plastics, especially high-strength or abrasive types of plastic, PCD milling cutters ensure clean cutting edges and minimize burr formation.

- Graphite: Graphite, which is mainly used in the electrical industry to manufacture electrodes, is very abrasive for conventional tools. PCD milling cutters, on the other hand, enable precise machining with a long tool life.

What are the advantages over conventional milling cutters?

PCD milling cutters offer numerous advantages over conventional tools such as carbide milling cutters or HSS milling cutters:

- Longer tool life: PCD tools are extremely resistant to wear, making them ideal for abrasive materials such as graphite, zinc or plastics. This reduces tool changes and increases efficiency.

- High machining speeds: PCD milling cutters make it possible to machine materials at high cutting speeds, which increases productivity and shortens cycle times.

- High precision and surface quality: Due to the extreme hardness and sharpness of PCD tools, materials can be processed very precisely and with minimal burr formation. This results in a high-quality surface finish.

- Reduced heat generation: Thanks to their high wear resistance and low friction, PCD milling cutters generate less heat, which increases the service life of the tools and improves the quality of the machined parts.

- Less reworking: The low burr formation and high precision reduce the need for reworking, which makes machining processes more efficient.

You can find PCD milling cutters here:

For high-quality PCD milling tools, the Diamond Toolingsystems DTS GmbH your reliable partner. We offer a wide selection of PCD milling cutters that have been specially developed for machining materials such as aluminum, brass, zinc, plastics and graphite. Visit our webshop or contact our team of experts directly to get the right tools for your individual requirements.

With PCD you can machine materials like:

- Aluminum <12%Si

- Zinc

- Brass

- Plastics

- GFRP (*First choice CVD-D)

- CFRP (*First choice CVD-D)

- Copper

- Coarse-grained graphite

- Ceramic green compact

- Carbide green compact

Contact us!

DTS GmbH

Hans-Geiger-Strasse 11a

D-67661 Kaiserslautern

Customer service

Mo. - Fr. 8:00 - 16.30 Uhr

Contact details

F: +49 (0) 6301 32011-90