CVD thick film diamond (CVD-D), the star among diamond cutting materials

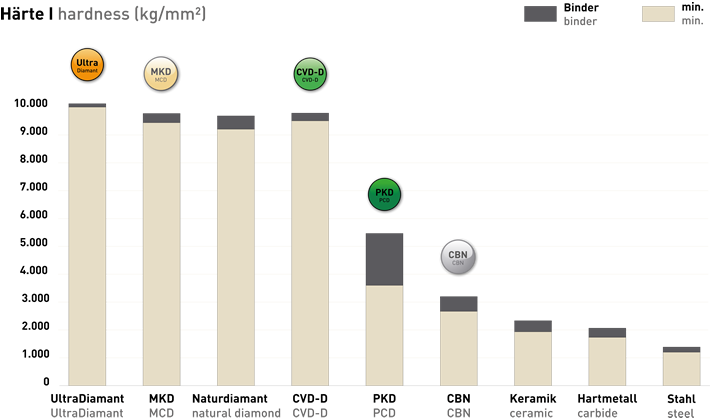

For machining hard-brittle materials such as ceramics, glass and glass-ceramics, hard metal, MMC and fibre composites such as CFRP and GFRP. Due to the lack of a bonding matrix, the diamond content is much higher than with PCD. In the group of ultra-hard cutting materials, binderless CVD-D is one of the hardest, artificially produced diamond cutting materials.

CVD-D is characterised by a high hardness as well as a high wear resistance. These properties make CVD-D the perfect cutting material for machining abrasive materials. Compared to PCD, which is damaged by the abrasive particles due to its soft metallic binder phase, the CVD-D cutting edge remains stable due to its binderless anchoring in the diamond matrix.

If CVD-D is used correctly, the tool life can be increased by up to 10 times (and even more) compared to PCD!

With CVD you can machine materials like:

- Aluminum >10%Si

- GFRP

- CFRP

- MMC

- Carbide >8% Co

- Tungsten copper

- Tungsten

- Graphite fine-grained

- Magnesium

Contact us!

DTS GmbH

Hans-Geiger-Strasse 11a

D-67661 Kaiserslautern

Customer service

Mo. - Fr. 8:00 - 16.30 Uhr

Contact details

F: +49 (0) 6301 32011-90